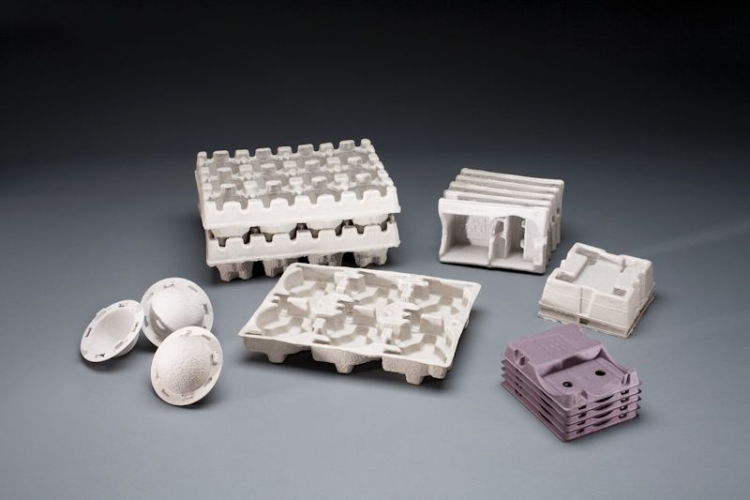

Molded pulp or molded fiber is a packaging material that is regularly produced using recycled paperboard and additionally newsprint. It finds applications for protective packaging or food plate and drink transporters. Other regular uses are end covers, plates, plates, bowls, and clamshell holders. For some applications, molded pulp is more affordable than extended polystyrene (EPS), vacuumed framed polyethylene terephthalate (PET), and polyvinyl chloride (PVC), layering, and froths. Molded pulp is regularly viewed as a sustainable packaging material, as characterized by the Sustainable Packaging Coalition, since it is delivered from reused materials, and can be reused again after its helpful life-cycle.

Shaped mash items can be made waterproof with a shower or plunge covering of wax. Molded pulp is a spotless, wood-based, or bagasse sugarcane, sustainable and biodegradable crude material typically produced using reused squander-based paper/cardboards or Virgin Fiber. While moderately new contrasted with a portion of the more customary paper packaging materials, mash’s ubiquity and notoriety as the go-to sustainable packaging choice for enormous, bespoke, hefty, little, and delicate items are quickly developing.

Molded pulp is a recycled packaging material intended to be reused by and by. Almost certainly, the mash fiber material you may have gone over would have filled numerous needs in its day-to-day existence. Because of the idea of mash, every one of its items can be reused in any family or public reusing focus. What’s more? If it ends up in nature, it will disintegrate in about a month and a half. Reasonable bundling should meet the beneficial and monetary requirements of the present without compromising the capacity of people in the future to address their issues. Maintainability isn’t an end state; however, a process with the interaction of improvement is.

Types

Thick-wall: These items, for the most part, have divider thicknesses of 1.5 to 6mm (1/16″ to 1/4″) and are utilized fundamentally for help packaging applications. Thick-Wall is additionally regularly alluded to as “Slush Molded.” The surfaces are harsh on one side and modestly smooth on the contrary side.

Transfer molded: Move-shaped items are generally slightly walled, 1/16″ to 3/16″, and are the most common sort found in use today. The interaction utilizes vacuum framing and take-off or moving molds, where the form is a very fine wire network looking like the upper/uncovered surface.

Thermoformed fiber: This freshest type of shaped mash is the greatest of meager walled items accessible today. The cycle utilizes “fix in-the-shape” innovation which creates distinct, smooth-surfaced formed mash items. For shaping, manufacturers place the item in warmed framing molds that presses and densifies the molded items.